HydroMax Seal

Leak-Free Operation for

Most Demanding Applications

- API 682 & 610

- USA-Made

- 24/7 Rapid Response

We Offer

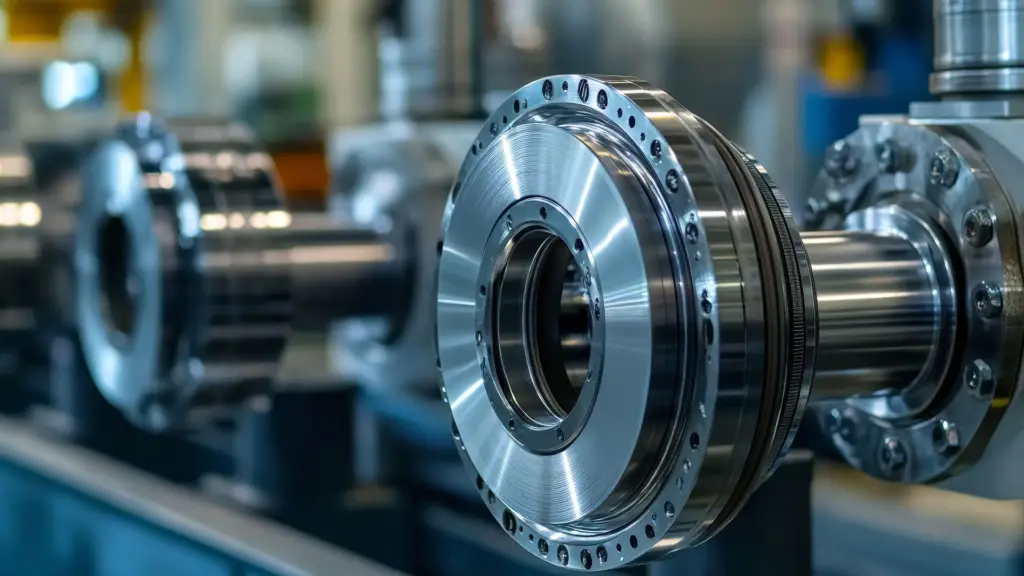

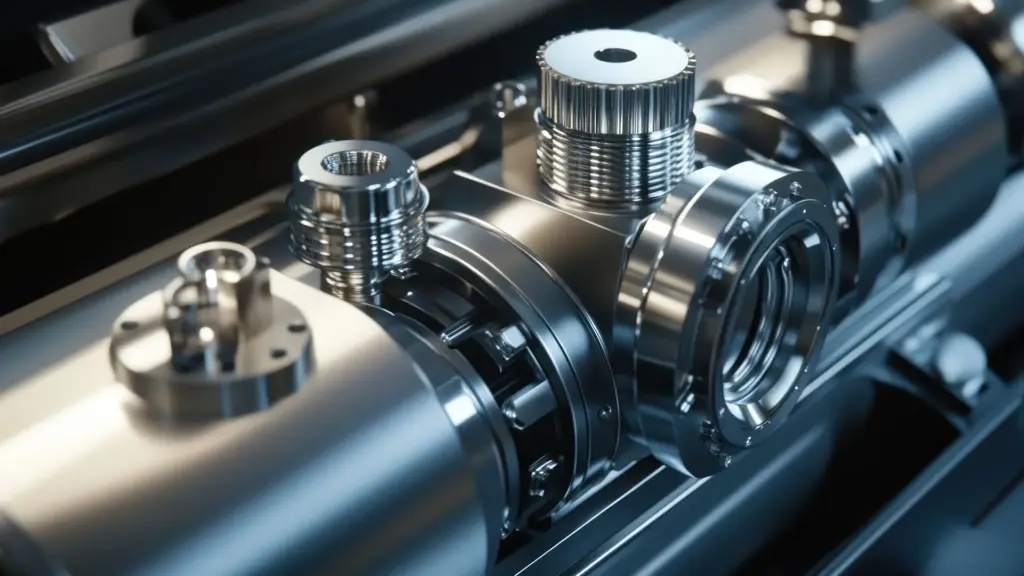

Mechanical Seals

Engineered for peak performance and long service life—minimizing leaks and costly downtime.

Pump Seals

Precision-crafted for efficiency and reliability, ensuring smooth pump operations.

Centrifugal Pump Seals

Built to withstand the toughest industrial conditions while optimizing pump performance.

Proven Expertise

You Can Trust

With over four decades of engineering excellence, HydroMax Seal delivers API-certified mechanical seals trusted by industries worldwide. Backed by advanced R&D, precision manufacturing, and 24/7 global support, we ensure reliability where it matters most.

Projects Work

Expert Team

Years of Experience

Our Seals

Explore Our Products

Cartridge Mechanical Seals

Reliable, pre-assembled seals that simplify installation and reduce downtime. Options include single- and double-cartridge designs, engineered for stability and long service life.

Component Mechanical Seals

Versatile single-spring, multi-spring, and bellows seals designed for broad industrial compatibility. Precision-built for durability and efficiency in critical operations.

Teflon Bellow Seals

Engineered for use with aggressive and corrosive fluids, these glass-filled Teflon seals provide exceptional chemical resistance and leak-free operation.

Bearing Seals

High-performance labyrinth seals like LAB-100, certified to IP69K, are designed to protect rotating equipment under extreme environments

Mixer & Agitator Seals

Heavy-duty seals for reactors and mixers, built to withstand high torque, temperature, and pressure. Options include single and double seals for GLR and ANFD systems.

ANFD Seals

Specialized seals for Agitated Nutsche Filter Dryers, crafted from stainless steel and exotic alloys. Provide stability under high axial shaft movement.

Pump Seals

A complete range of seals for centrifugal pumps, including multi-spring, metal bellows, and cartridge types, tailored for maximum pump efficiency

Slurry Seals

Designed for abrasive and particle-laden fluids in mining, pulp, and wastewater industries. Compact and double cartridge models ensure high sealing integrity.

Plan 54 Circulation Systems

Forced oil circulation units with pumps, heat exchangers, and monitoring for extreme duty. Built to maximize seal life in the petrochemical and power industries

Seal Support Systems

Thermosyphon, thermal, and water-based support systems that regulate pressure and temperature. Compact, stainless steel units ensure reliable barrier fluid management

Equipment Specific Seals

Custom-engineered seals for OEM pumps and rotary joints, including Grundfos, Fristam, and FLOWSERVE MkII compatible designs

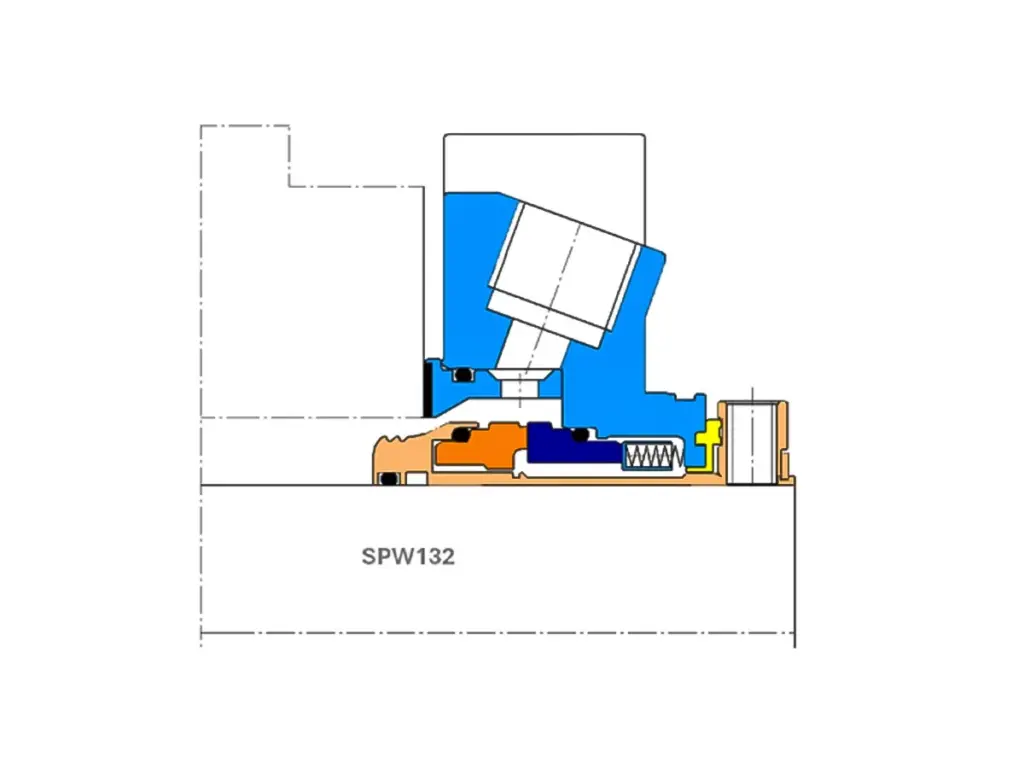

API 610 Seals

Engineered to meet API 610 standards for centrifugal pumps in oil, gas, and petrochemical industries. Compact single-cartridge models with vortex breakers and flush ports

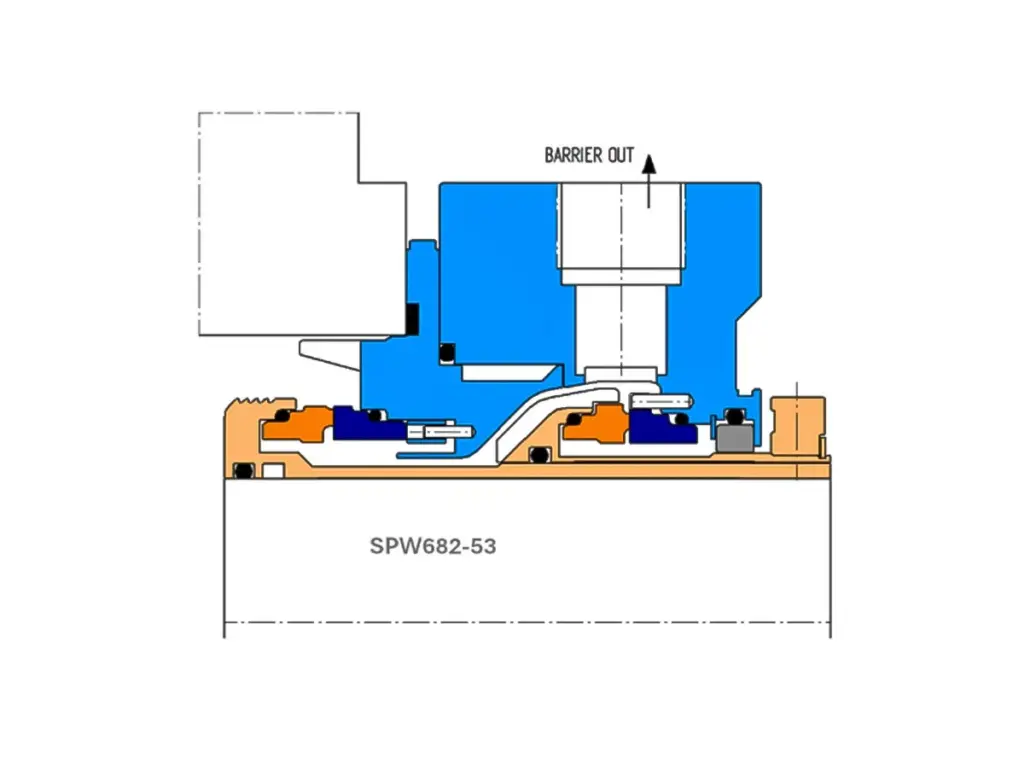

API 682 Seals

High-performance single, dual, and tandem seals compliant with API 682 standards. Built for leak-free operation, emissions control, and long-term reliability in critical service

Need to solve a seal problem today?

Talk to our engineers or request a Service Quote to get started.

Services

Our Service Capabilities

At HydroMax Seal, we deliver end-to-end support designed to maximize seal life, uptime, and performance in demanding industrial environments. From precision R&D to emergency response, here’s how we help:

Seal Performance Solutions

At HydroMax Seal, we deliver end-to-end support designed to maximize seal life, uptime, and performance in demanding industrial environments. From precision R&D to emergency response, here’s how we help:

- Reduce unplanned downtime

- Increase equipment availability

- Lower lifetime costs

Precision Engineering & Innovation

Custom design & engineering: CAD/FEA, material selection, solutions for high-temp, high-pressure, corrosive environments.

- Fit-for-purpose seal designs

- Higher performance under extreme conditions

- Reduced maintenance overhead

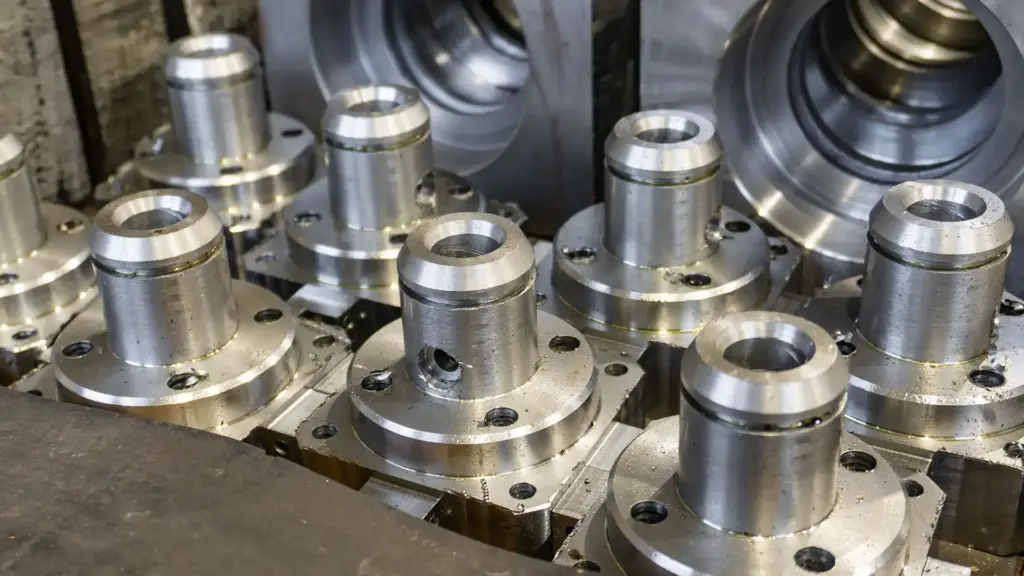

Advanced Seal Manufacturing

Full manufacturing capabilities: CNC machining, grinding, lapping; working with exotic materials like carbon, SiC, PTFE, etc.

- Tight tolerances

- Leak-proof sealing surfaces

- Consistent quality across batches

Assembly & Quality Testing

ISO-9001-aligned assembly, pressure & leak testing, simulation of real operating conditions before delivery.

- Fewer field failures

- Smooth commissioning

- Assurance of performance before installation

Smart Inventory & Rapid Response

Proactive spare parts & seal kit stock, fast dispatch, emergency restocking systems.

- Less waiting

- Faster turnarounds in critical situations

- Support when time matters most

Expert Seal Repair & Refurbishing

Restoring seals (including competitors’) to OEM-grade condition using advanced restoration techniques and strict inspections.

- Cost savings vs new seals

- Environmentally sustainable

- Maintains performance and reliability

Why Choose These Services

- Designed to reduce unplanned shutdowns and maintenance costs.

- Tailored for critical rotating equipment and harsh industrial conditions.

- A combination of proactive maintenance and reactive support provides both protection and peace of mind.

The HydroMax Advantage

Pioneering R&D

- Industry-leading seal testing lab with 2,000+ hours of validation per design.

- 37 patented technologies deployed worldwide.

Uncompromising Standards

- Dual API 682/610 Category 1 certified and ISO 9001:2015 accredited.

- Seals are built with 100% traceable, aerospace-grade materials.

Global Support Network

- 24/7 emergency response from Houston, Rotterdam, and Dubai.

- On-site optimization programs at Siemens, Chevron, and BASF facilities.

Proven Performance

- 98.7% MTBF – triple the industry average.

- <50 ppm leakage, exceeding EPA & EU mandates.

FAQs

Frequently Asked Questions

What industries use HydroMax Seal products?

We serve oil & gas, petrochemical, power generation, mining, water treatment, and general industrial sectors.

Do your seals comply with API standards?

Yes. HydroMax is dual-certified for API 682 and API 610, ensuring compliance with global sealing standards.

Can HydroMax seals handle corrosive or abrasive media?

Absolutely. We engineer seals with advanced materials, such as carbon, SiC, and glass-filled PTFE, for use with harsh fluids and slurries.

Do you offer custom-engineered sealing solutions?

Yes. Our engineering team designs seals tailored to your equipment, operating conditions, and industry requirements.

How quickly can I get a replacement seal?

We maintain smart inventory and offer 24/7 emergency response, with rapid shipping from Houston and global hubs.

Can HydroMax repair or refurbish seals?

Yes. We provide comprehensive seal refurbishment and testing, restoring units to their original OEM-grade performance.

What testing do HydroMax seals undergo?

Every design undergoes 2,000+ hours of lab validation under extreme conditions, including high pressure, high temperature, and corrosive fluids.

How long do HydroMax seals typically last?

Our seals achieve an average MTBF of 98.7%, nearly three times the industry standard.

Do you support OEM equipment compatibility?

Yes. We manufacture seals compatible with Grundfos, Fristam, FLOWSERVE, Siemens, and other OEM equipment.

How can I request a quote?

Simply email sales@hydromaxseal.com or use the Request a Quote form on our site.

Get in Touch

Have a question about our products or services? Need a quote for your next project? Our team is ready to assist you with technical guidance, product inquiries, and order support. Contact us today and we’ll get back to you promptly.

- sales@hydromaxseal.com

- 18511 Beaumont Hwy, Building D, Houston, TX 77049