HydroMax Seal

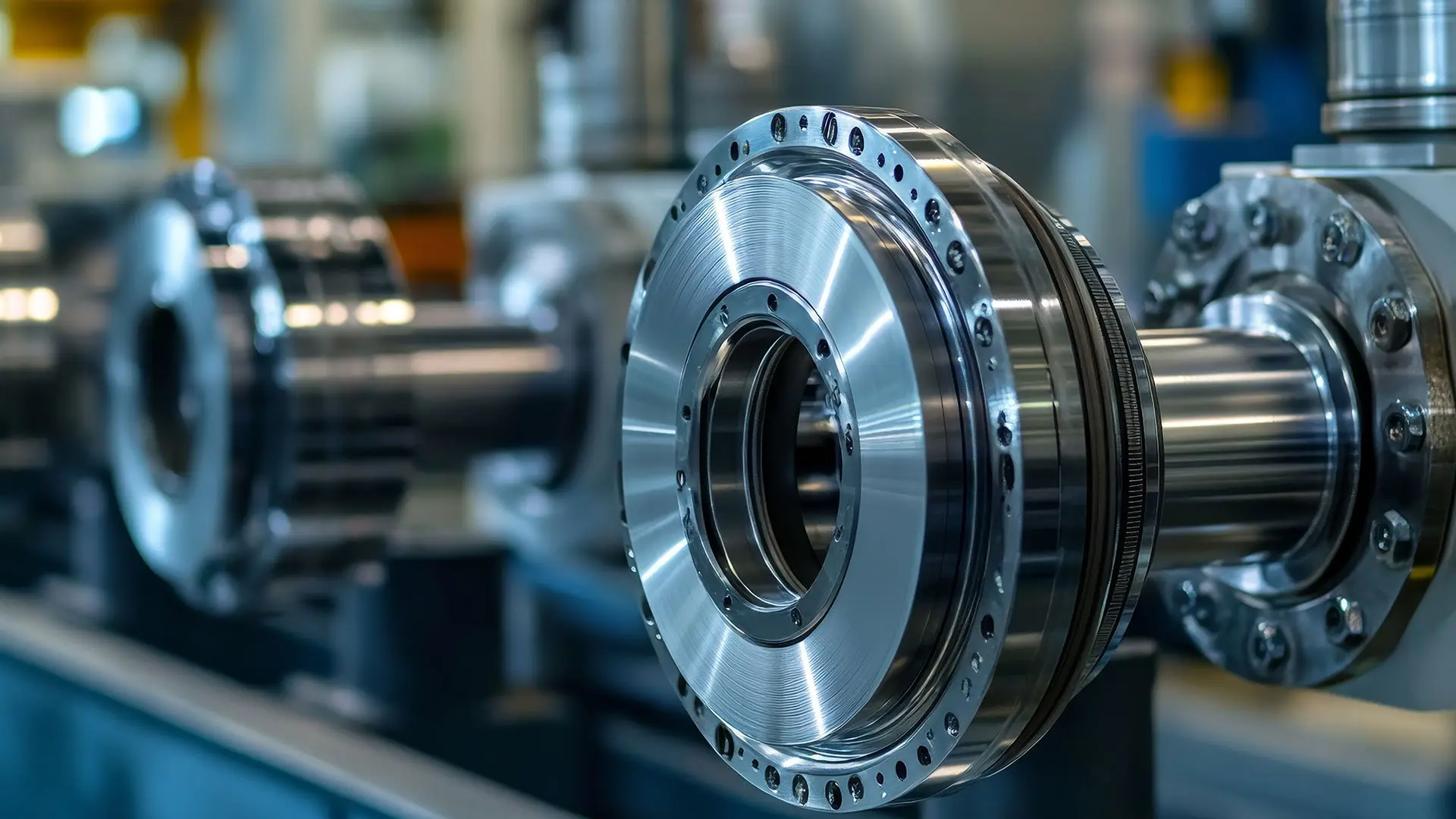

HydroMax Industrial Pump Seal - Maximize Pump Life with Heavy-Duty Industrial Seals

Extend pump life, reduce costly downtime, and ensure consistent performance with HydroMax high-precision pump seals — built for demanding industrial applications.

- API 682 & 610

- USA-Made

- 24/7 Rapid Response

The Hidden Costs of Failing Pump Seals

When pump seals break down, operations suffer. Leaks, unplanned shutdowns, and frequent replacements not only disrupt production but also drive up maintenance costs. Standard seals often fail under extreme pressure, high temperatures, or corrosive fluids — putting your equipment and bottom line at risk.

Our Solution: Industrial Pump Seals That Deliver Lasting Protection

HydroMax industrial pump seals are engineered to solve the challenges that standard seals can’t. Built from premium materials and precision-tested for high pressure, temperature, and corrosive environments, our seals stop leaks before they start. The result: longer pump life, lower maintenance costs, and consistent reliability across critical operations.

Key Advantages:

Leak-Free Performance – Prevent costly fluid loss and equipment downtime

Engineered Durability – Withstand extreme pressure, heat, and abrasive media

Industry-Ready – Trusted in chemical, oil & gas, power, wastewater, and food processing

Explore HydroMax’s Leading Pump Seal Lineup

CSW-610 – Compact Double Cartridge Seal

- Space-saving design for pumps with narrow cross-sections

- Bi-directional barrier fluid pumping for efficient cooling

- High-temperature and high-speed reliability

SPS-610 – Double Cartridge Seal for Slurries

- Built for slurry service with suspended particles

- Vortex breakers for stable operation in solid-laden fluids

- Robust design for mining, pulp & paper, and wastewater

SPS-625 – Heavy-Duty Double Cartridge Seal

- Wear-resistant components for severe slurry conditions

- Fully outboard mountable for compact seal chambers

- Extended service life in mining and heavy-duty industries

RPW-215 – Balanced Single Cartridge Seal

- Multi-spring balanced design with flush & quench ports

- Simplified installation with pre-set face load

- Reliable sealing for a wide range of rotating equipment

SPW-516 – Double Cartridge Seal with Flow Inducer

- Integral flow inducer for directed barrier fluid circulation

- Self-aligning seal faces for misalignment tolerance.

- Suitable for demanding, high-temperature applications

Application

Where HydroMax Pump Seals Make the Difference

HydroMax industrial pump seals are designed for the most demanding environments, where equipment uptime and reliability are paramount. By maintaining leak-free operation and longer service life, our seals help operators minimize unplanned shutdowns, reduce energy consumption, and lower maintenance costs.

From Application to Solution: The Right Seal for the Job:

Compact, High-Speed Pumps

For pumps with short outboard lengths and narrow seal chambers, the CSW-610 Compact Double Cartridge Seal ensures reliable cooling and stable sealing performance

Slurry and Solid-Laden Fluids

In abrasive services such as mining and wastewater, the SPS-610 Double Cartridge Seal delivers stability and durability under heavy particle loads.

Severe Slurry Operations

Where extreme wear and turbulence are common, the SPS-625 Heavy-Duty Double Cartridge Seal provides extended life and resistance to failure

General Industrial Pumps

The RPW-215 Balanced Single Cartridge Seal offers versatile, cost-effective sealing with flush and quench options for diverse process equipment

High-Temperature, Demanding Services

The SPW-516 Double Cartridge Seal with Flow Inducer directs barrier fluid circulation for dependable performance in hot or chemically aggressive streams

Performance Benefits:

By addressing these critical challenges, HydroMax pump seals reduce the total cost of ownership through fewer replacements, lower labor demands, and improved energy efficiency, ensuring long-term reliability and measurable ROI.

Your Next Seal Solution Starts Here

Why replace when you can refurbish for less? Our refurbishment services restore mechanical seals to peak performance at a fraction of the cost. Start saving on maintenance today.

- sales@hydromaxseal.com

- 18511 Beaumont Hwy, Building D, Houston, TX 77049

Request a Free Quote Today

FAQs

Frequently Asked Questions

What pressure and temperature ranges can HydroMax pump seals reliably handle without compromising face stability?

Our seals are designed for process pressures up to 20 Barg (290 psig) and temperatures reaching 180°C (356°F), depending on the model. Balanced designs and shrink-fitted seal faces ensure stability under combined pressure and thermal stress.

How do your seals maintain integrity when pumping fluids with abrasive particles or high slurry content?

Specialized slurry-duty designs like the SPS-610 and SPS-625 use vortex breakers, wear-resistant faces (Silicon Carbide or Tungsten Carbide), and optimized barrier fluid circulation to resist erosion and maintain sealing performance in particle-laden streams.

Are the seals API 682 compliant, and which piping plans are supported (e.g., Plan 53A, 53B, 53C)?

Yes, HydroMax cartridge seals are designed in line with API 682 best practices and support common piping plans, including Plan 52, 53A, 53B, and 53C, making them suitable for standardized global operations.

Which pump models and shaft sizes are your cartridge seals designed to fit without modification?

Our seals cover shaft sizes from 20 mm to 100 mm (1.0”–4.0”) and are engineered to retrofit into most standard ANSI, ISO, and API pump models. Application-specific ranges are also available for OEM pumps such as Flowserve and Fristam.

Do your seals allow for retrofit into existing equipment, or do they require custom hardware adjustments?

Most HydroMax cartridge seals are drop-in ready, requiring no equipment modifications. For legacy or non-standard pumps, we provide engineered solutions to ensure compatibility without major redesign.

What is the typical installation time for your pre-assembled cartridge seals compared to component seals?

Cartridge seals are shipped pre-set and factory-tested, reducing installation time by up to 60% compared to component seals. This minimizes downtime and eliminates the need for precise on-site face setting.

How do your seals manage barrier fluid circulation to prevent heat buildup in continuous-duty applications?

Models like the SPW-516 integrate flow inducers and engineered porting to direct barrier fluid across seal faces. This ensures effective cooling, prevents dry running, and extends service life under continuous operation.

What is the expected service life under high-cycle or 24/7 operation, and how does refurbishment extend that life?

Service life varies by application, but HydroMax seals typically run 12–24 months in heavy-duty operations. Our refurbishment program restores seals to their original specifications, extending their total usable life by another 1–2 cycles at 40–60% of the new cost.

What condition monitoring practices (leakage detection, flush port inspections, etc.) do you recommend for predictive maintenance?

We recommend routine inspection of flush and quench ports, monitoring barrier fluid levels, and watching for minor visible leakage — often the first sign of wear. Integrating seal support systems with pressure and temperature sensors provides predictive data to plan replacements proactively.

How does refurbishment pricing compare to new replacements, and what are the cost savings over a 5-year lifecycle?

Refurbished seals typically cost 40–60% less than new. Over the course of 5 years, customers often achieve up to 50% lower total spend on sealing solutions by alternating between new purchases and refurbishment cycles.